The Navy continues to make improvements on its overall ship maintenance performance, but the cruisers undergoing modernization overhauls are running behind schedule and contributing to expected delays this fiscal year, the head of Naval Sea Systems Command told reporters today.

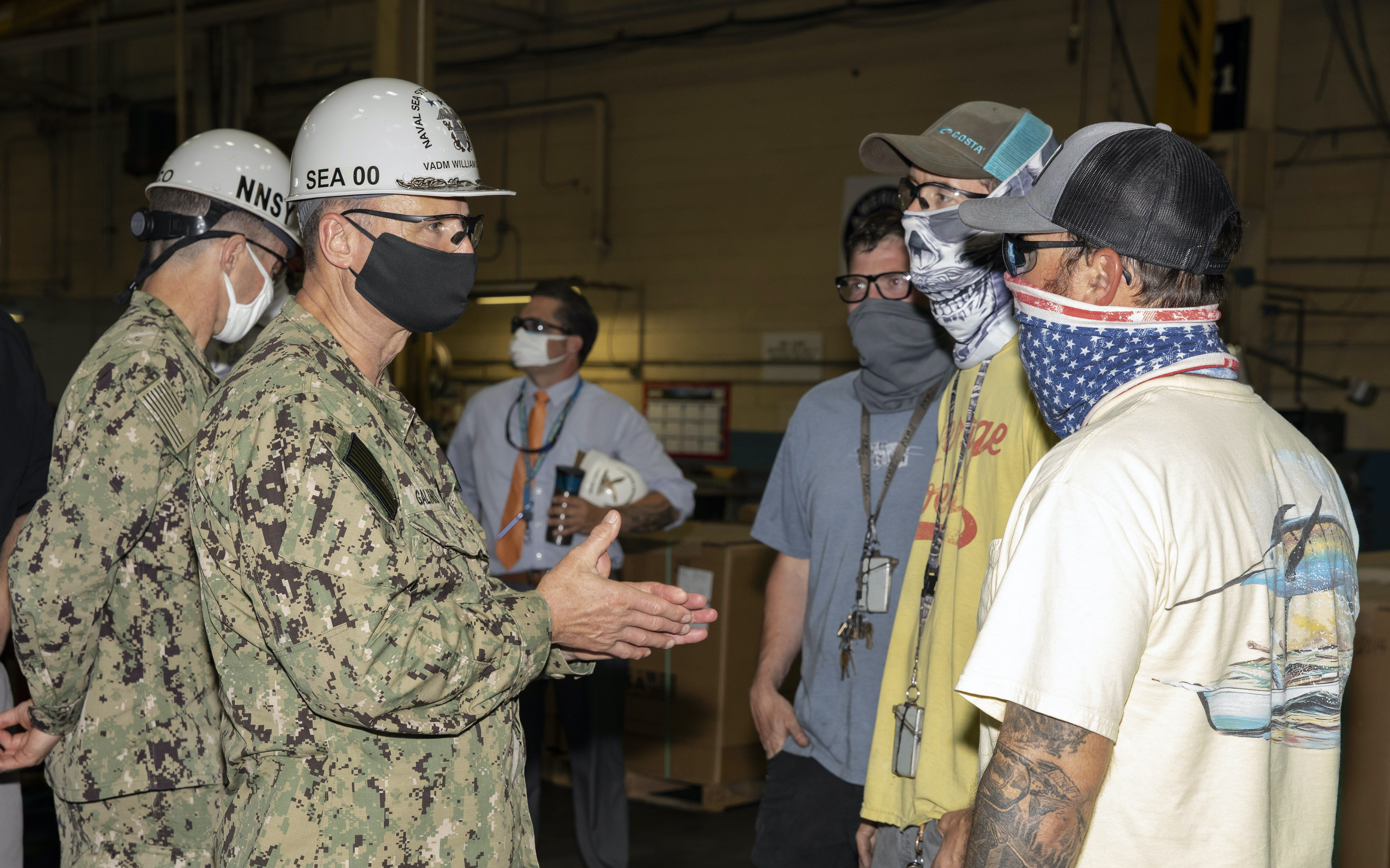

Vice Adm. Bill Galinis said in a Defense Writers Group event Thursday that “overall we absolutely made significant improvement in [Fiscal Year 2020] compared to FY19.” USNI News previously reported the Navy dropped from more than 7,000 days of delays to about 1,100 in FY 2020, though some of that was due to new metrics that give, the Navy says, a more realistic timeline for how long certain maintenance activities should work.

Galinis said today that, if the ships were held to the new baselines, there was an 80-percent drop in days lost due to overruns. If those ships were held to their original timelines then there was still a 40-percent drop in days lost from FY 2019 to FY 2020, he added.

Still, the Navy had stated in January that it hoped to reach zero lost days by the end of FY 2021, this current fiscal year – and today Galinis said that that just wouldn’t happen.

“Going forward, what I would tell you is we’re not going to get to 0 in ‘21, I’ll just tell you that right upfront. We understand why that’s not going to be, there are I’ll say a half a dozen ships in particular that will just go long,” he said.

Four cruisers undergoing the modification effort are part of the problem, as is USS Oscar Austin (DDG-79), which suffered a fire in November 2018 while undergoing maintenance and is now significantly behind schedule.

“We’re not going to make the goal we set for ourselves, but we understand the discrete drivers behind that,” Galinis said. He added that “that’s not to say there won’t be other ships that are out there” that could be at risk of delays, “and we continue to manage that.”

Today, two-thirds of ships undergoing maintenance are tracking to complete on time, compared to less than 50 percent at this time last year, he said.

“We’re moving the needle in the right direction, but there’s still a lot of work to do there,” the vice admiral said.

On the cruiser modernizations, Galinis told USNI News during the call that “we understand kind of where we are with that; we’re in the process right now, working with Navy leadership and with the shipyards, to, I’ll say, re-baseline that program.”

After much back and forth between the Navy and Congress, the cruiser modernization plan was meant to follow a 2-4-6 rule: the Navy would induct two cruisers a year, for work not to last more than four years each, totaling no more than six cruisers in the program at any given time.

As for the other ships undergoing maintenance that the Navy-industry team are trying to keep on time, Galinis said two big drivers are changes to the work package once maintenance has begun, and material availability.

Adding work once a ship begins its maintenance “becomes one of the principal drivers that drive availabilities long. So it’s almost kind of a case-by-case, ship-by-ship explanation” of how the Navy and the repair yards are tamping this down.

“What I will tell you is that, I think over the last several years [the Surface Maintenance Engineering Planning Program (SURFMEPP) has] done a really good job of building and stabilizing the class maintenance plan. And that’s kind of what we refer to as directed work, and we’re trying to push more work, more maintenance work into that directed work category, if you will. And what that does is it really provides a pretty stable baseline in terms of requirements and planning for a larger percentage of the work we’re doing in an availability.”

Prior to this effort, certain maintenance items might have been left to a wait-and-see approach and more times than not needed to be done – but the materials might not be on hand, or it might be tougher to squeeze it into the work schedule at the most efficient time. Acknowledging up front that these maintenance items will definitely be done helps plan for them more efficiently.

On the material side, Galinis said that in the past material has been ordered too late, or it was ordered on schedule but took longer to deliver than expected – both of which leads to delays at the repair yard. Galinis previously told USNI News that a Material Management Group had been stood up on the private shipyard side and was in the process of being stood up on the public naval shipyard side.

As for the impact of the COVID-19 pandemic, Galinis said during the media call that about 90-percent of the workforce was coming to work at the public yards on any given day, with attendance for production trades being a bit lower at around 88 percent. That compares to a usual attendance rate of about 92 to 94 percent pre-pandemic. He said the COVID impact has varied a bit from yard to yard, but the smaller Portsmouth Naval Shipyard and Pearl Harbor Naval Shipyard and Intermediate Maintenance Facility are faring better than the larger Norfolk Naval Shipyard and Puget Sound Naval Shipyard and IMF.

At private yards, the attendance rates vary from yard to yard based on how the local communities are faring, but he said they tend to be in the upper 80s to low 90s.

“That has had an impact as well on availability performance,” he said.

Galinis said during the call that, as the Navy plans to grow in the coming decades – perhaps to 500 manned and unmanned ships, under a new Pentagon plan – that on-time maintenance will become more important. The Navy will certainly need more maintenance capacity, but some capacity can be created simply by getting ships out of repair on time and getting the next ships in as quickly as possible.

In the long term, “we’ve got maintenance capacity issues within some of our repair yards, and then just capacity issues kind of in some phases of our new construction yards that we have to get after,” he said.

“I don’t see them as insurmountable, but we really need to kind of look at how we’re doing business. One of the ways, I’ll just tell you, is just finishing ships on time: that in itself will free up capacity.”