A Mississippi shipyard started fabricating on what will be the first components for a new fleet of heavy U.S. icebreakers, the company announced on Wednesday.

Bollinger Shipyards cut steel of the first of eight modules that will become part of the first Polar Security Cutter – the future USCGC Polar Sentinel (PSC-1). The prototype modules are being built as a proof-of-concept for the cutter but, if approved, will be incorporated in the first icebreaker.

The 23,000-ton Polar Security Cutters are the first class of heavy icebreakers the U.S. has built since the 1970s. Originally awarded in 2020, the program has suffered delays with the lead hull delayed by about three years. The first estimate for the initial three hulls was $2.7 billion, with the initial PSC to deliver in 2025. However, the Coast Guard is reassessing the cost of the program, a Coast Guard spokesperson told USNI News last month.

Now, the design isn’t set to be completed until 2024, and the first cutter won’t be ready to sail until 2028. Ahead of the design approval, estimated for next year, work on the prototype modules will prove the yard in Pascagoula, Miss., will be ready to construct the ship.

“Before the full construction process on the PSC program begins, the prototype modules test the new systems, processes, people, and tools that are required to work with the specialized steel. The lessons learned from building the prototype module will be used to help ensure design completeness,” reads a statement from the yard.

“Each module requires approximately four months of labor, during which time Bollinger will continue recruiting and training additional members of the workforce to manage the transition to production of the lead hull as the prototype modules are completed.”

The icebreaker will be built out of specialized steel known as EQ-47, which is both strong and tolerant of lower temperatures that require special skills to handle, USNI News reported last week. Additionally, the design of the icebreaker requires more work from shipbuilders to construct.

The icebreaker will be built out of specialized steel known as EQ-47, which is both strong and tolerant of lower temperatures that require special skills to handle, USNI News reported last week. Additionally, the design of the icebreaker requires more work from shipbuilders to construct.

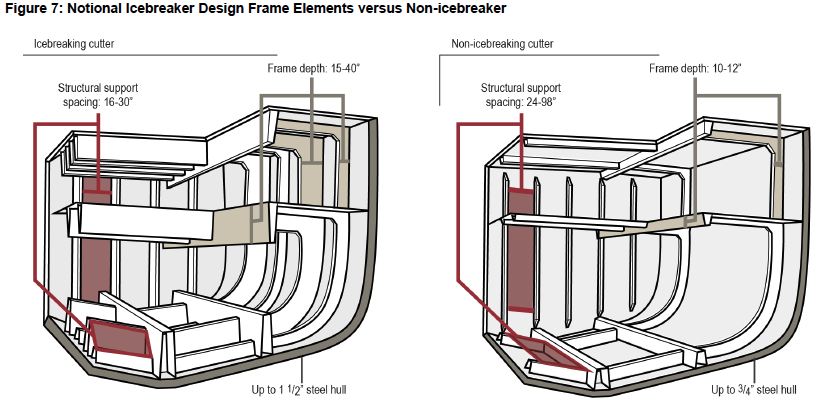

“The design also calls for more closely-spaced structural framing within the hull to add strength, especially within the icebelt area of the cutter,” a recent Government Accountability Office report reads. “According to shipyard representatives, this will increase production time due to the challenges of getting a welder inside the smaller spaces to work and limiting the time they can work there because of the close proximity to the heat produced while welding. Shipyard representatives also told us that as a result of this close spacing, there is less space to route equipment such as cables and pipes.”

The design of Polar Sentinel is based on the yet-to-be-built German icebreaker Polarstern II but was heavily modified for the Coast Guard’s mission.

“We’re relearning how to build this type of ship,” Coast Guard PSC program manager Capt. Eric Drey said. “It’s the first heavy icebreaker built by our nation in 50 years. It’s not just a big day for the Coast Guard, but a big day for the nation.”

In the meantime, the service has requested $125 million to purchase a commercial icebreaker as part of its Fiscal Year 2024 budget submission.