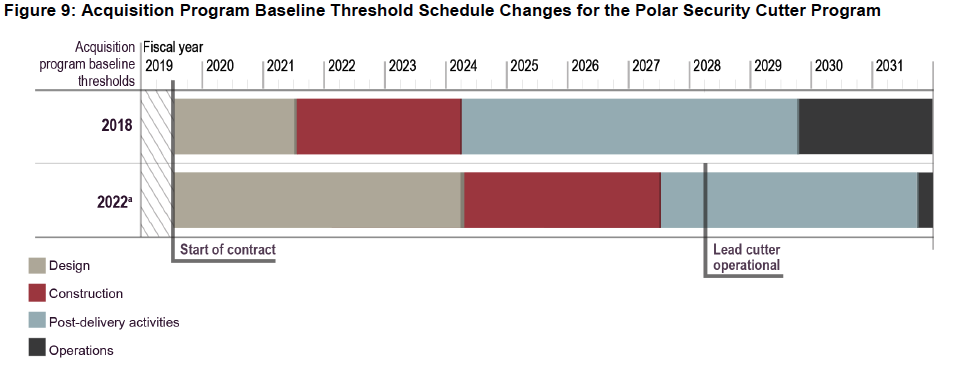

The design for the U.S. Coast Guard’s long-gestating heavy ice breaker won’t be ready until next year and the first hull likely won’t deliver until 2028 – three years later than the original estimate – according to a new Government Accountability Office report reviewed by USNI News.

According to the estimate from GAO, which cites Coast Guard and Navy officials, as well as shipbuilders – the final design for the 23,0000-ton ice breaker won’t be complete until next March. Construction is scheduled to start shortly after the design is approved. Coast Guard commandant Adm. Linda Fagan told Congress last month that the delivery of the first hull is expected in 2028.

“I am confident we are going to begin building that ship as we go into the next calendar year, early in the next calendar year,” Fagan told a Senate panel on July 13. “It’ll be at least a four-year project to build that ship.”

The Coast Guard and the Department of Homeland Security, working with Naval Sea Systems Command, awarded the cutter contract in 2020 to VT Halter Marine’s yard in Pascagoula, Miss. The Coast Guard exercised a second hull option to 2021. The initial estimate for the first three hulls was $2.7 billion, with the initial PSC to deliver in 2025. However, the Coast Guard is reassessing the cost of the program, a Coast Guard spokesperson told USNI News last month.

The GAO report says that the initial time and cost assessments were overly optimistic,. The GAO blames U.S. officials’ inexperience building and designing icebreakers, the unique complexities of the PSC design, changes from the original design and COVID-19 complications for the construction delay. Also, in the middle of the design process, Halter Marine sold its Mississippi yard to Bollinger Shipbuilding and the Louisiana company took over the design work.

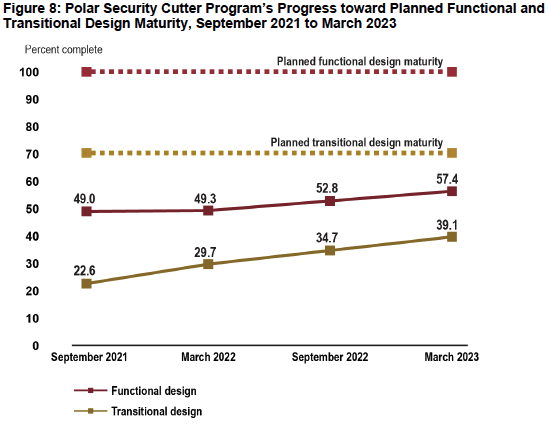

“Bollinger Shipyard representatives told [the GAO] that the biggest challenge they identified for the program since they took over the shipyard in November 2022 is advancing the engineering and design to a point where construction can begin,” reads the GAO report. “They told us that they have embedded their own design experts with the design subcontractor to help work through issues and provide additional expertise.”

The PSC is based on a heavily modified German design for the yet-to-be-built Polarstern II. The designers have made several changes in order to accommodate Coast Guard requirements. The design drawings also must be approved by the American Bureau of Shipbuilding.

The shipyard has also evolved the PSC design from the original design it proposed before contract award. After the contract award, VT Halter Marine worked with its design subcontractor to modify its proposed design to meet Coast Guard requirements for the PSC. According to program officials, the shipyard likely overestimated the extent to which it could leverage this original design and underestimated the magnitude of the design changes required to meet PSC requirements.

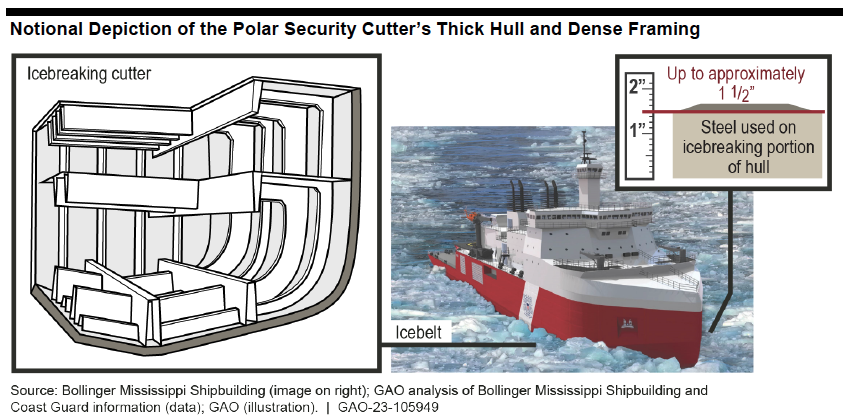

“Program officials stated several factors make the PSC design more complex than a non-icebreaking ship,” reads the GAO report. “For example, designers have to balance hull design features between what is needed for effective icebreaking—namely a blunt, relatively flat hull to break ice—and what is needed for good ship handling—namely a more streamlined hull that is traditionally U or V shaped.”

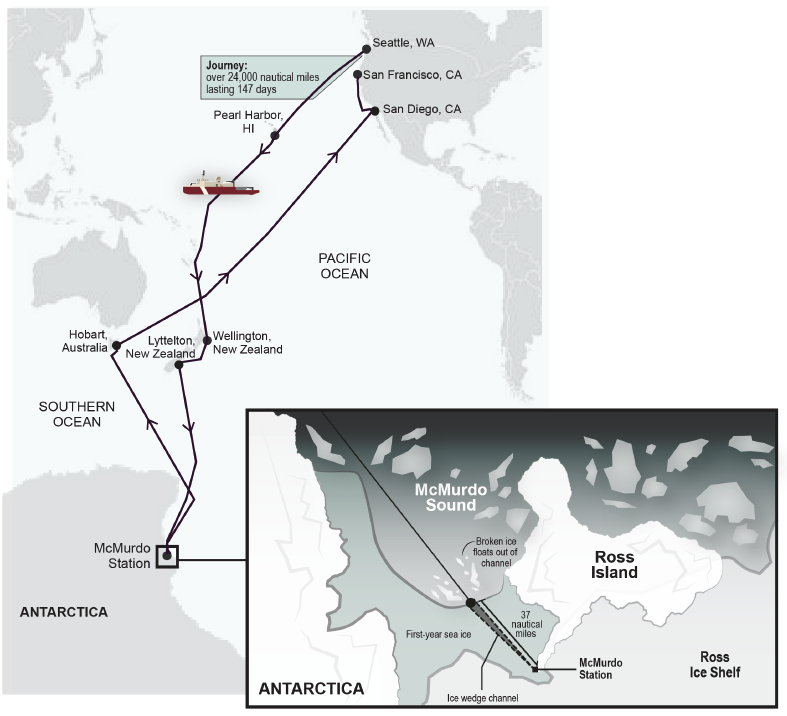

Unique to the Polar Security Cutter is the required transit for its ice-breaking mission. The current U.S. heavy icebreaker, USCGC Polar Star (WAGB-10), makes a yearly exodus from Seattle, Wash., to McMurdo, Antarctica to break out and resupply the American research station, a voyage called Operation Deep Freeze.

Polar Star’s round-bottom hull, while ideal for smashing the 17-mile-long ice path into McMurdo, is not ideal for the almost 12,000-nautical-mile transit from the U.S. to Antarctica. Polar Star is widely known as the “Polar Roller” for its poor seakeeping in the open ocean.

Additionally, the GAO cited the complexity of working with the special steel needed to reinforce the new icebreaker’s hull as a reason for additional delays.

“The ship structure adds complexity. For PSCs, the shipyard is using a steel alloy called EQ-47 that is high-strength and suited for use in low temperatures, but U.S. shipyards seldom use it in typical shipbuilding programs,” reads the GAO report.

“The design also calls for more closely-spaced structural framing within the hull to add strength, especially within the icebelt area of the cutter,” the report continues. “According to shipyard representatives, this will increase production time due to the challenges of getting a welder inside the smaller spaces to work and limiting the time they can work there because of the close proximity to the heat produced while welding. Shipyard representatives also told us that as a result of this close spacing, there is less space to route equipment such as cables and pipes.”

The Navy and Coast Guard also asked for 20 design changes from the original German design, including adding a shipwide computer network and modifications to the mooring system, which led to another year-long delay, the report said.

Some errors led to late-stage design mistakes, adding more months to the process, according to the report.

“Program officials told us the shipyard originally designed this deck too low in the ship for its intended purpose and had to move the deck because it would be susceptible to flooding if the ship sustained damage, but did not adjust the height of the new deck location. Once the shipyard realized this error, it had to increase the height of this deck. This subsequently required the resizing of tanks, such as those for fuel and potable water, in the cutter’s design. The shipyard finished incorporating these changes into the design by November 2022,” reads the report. “Bollinger Shipyard representatives who took over ownership after this design change occurred told us that the shipyard should have identified something this fundamental earlier in the process because it has spillover ramifications for other parts of the design.”

A Bollinger spokesman declined to comment on the report when contacted Tuesday by USNI News.

In the interim, the Coast Guard has asked for $125 million to purchase a commercial icebreaker as part of its Fiscal Year 2024 budget request.

“The most likely candidate is Aiviq, an ice-hardened tug supply vessel built by Edison Chouest in 2012 for $200 million,” Maritime Executive reported in May.