SAN DIEGO, Calif. – The Navy and many lawmakers want a massive increase in Navy spending but haven’t yet put forward a plan to start ramping up spending – and one shipbuilding executive said he wouldn’t feel comfortable investing in a larger workforce until certain signs of Navy commitment appear in the budget.

Mike Petters, president and CEO of Huntington Ingalls Industries, told USNI News last week that his company is already investing $1.5 billion in technologies and processes that can “reset our efficiency and our competitiveness,” but to support a ramp-up to 355 ships his yard would need to expand its workforce. And he’s not ready to do that just yet.

“There’s a lot of things that have to happen if we decide we’re going to invest against that. Some of it is, you’ve got to get rid of sequestration. You’ve got to get to some kind of normal order on the Hill,” he said.

“But you can do some programmatic things that make sense right now: you could change the way you buy aircraft carriers. When we built up the last time we bought them two at a time, so let’s buy them two at a time again. You wouldn’t see that for a decade or so, but the point is making those decisions now would then create the confidence to go invest in that ramp-up.

“To get to the numbers they’re talking about, I think you’ve got to build stuff you’re already building. You expand the rate of production for submarines and destroyers, and I think you can do that, and if you make the decision to do that in the next multiyear procurements that happen, that will create the investment profile that you need,” he continued.

“And then I think around amphibs and auxiliaries, you can make commitments – like in the amphib case, you can accelerate the LX(R) to take advantage of the production line that’s there. For auxiliaries you’ve got production lines that are mature, let’s take advantage of those production lines. And if you do those things, you can efficiently, actually, build up the size of the fleet.”

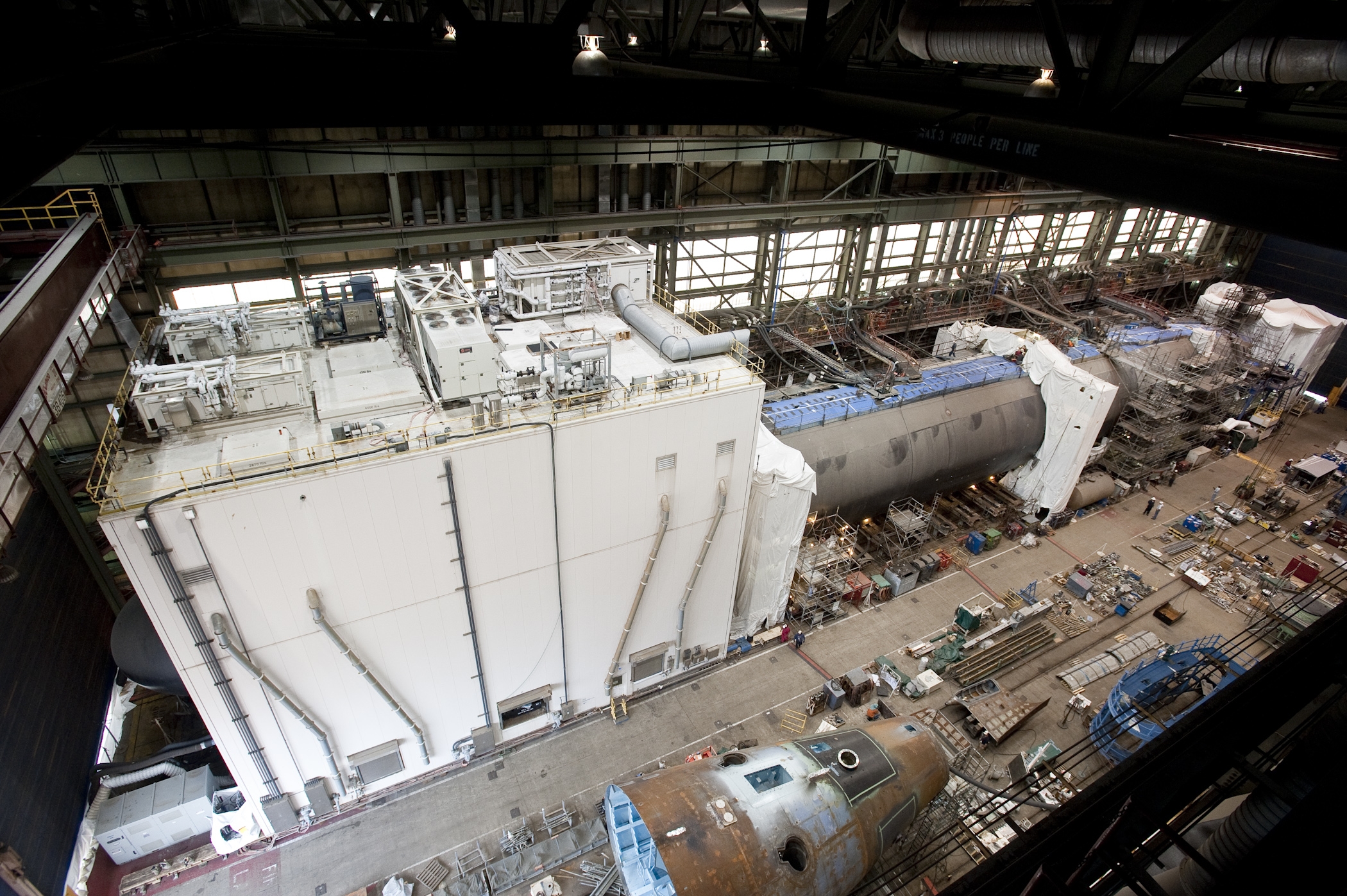

HII is well situated to support the early stages of a fleet expansion, given the company’s role in the three main ship classes being targeted for early production rate increases: HII is the sole builder of amphibious warships today at its Ingalls Shipbuilding yard, Ingalls is one of two yards building Arleigh Burke-class destroyers, and its Newport News Shipbuilding yard works alongside General Dynamics’ Electric Boat shipyard to co-produce Virginia-class attack submarines.

Petters said he was confident the two yards had the physical space to accommodate higher paces of production for these three classes, or to take on new work.

“The issue is not about footprint, the issue is about workforce,” he said.

“We can go and get the tooling and the work site, the job site, we can do all that a whole lot faster than the government can actually appropriate the funds to go do that, or make decisions to go do that. The question is, can you create the workforce fast enough? And we’re actually pretty good at that, but it’s not something you just start late; you’ve got to start early on that. So that’s kind of the way we think about it, as we start to see some of these programmatic decisions being made, then you go and start creating the workforce to go make it happen, which adds to the efficiency and makes it cheaper.”

The Navy is still awaiting a supplemental budget to add funding to the current fiscal year – potentially as much as $40 billion across the Defense Department – but much of that is likely to support maintenance, modernization and operations for current platforms. But the Fiscal Year 2018 budget, expected to be sent from the White House to Congress in early May, could contain some of the signs that Petters said might spur some hiring at his yards.

“The two-ship buys for carriers, increasing volumes of submarines and destroyers, accelerating the amphibs: those things are in the realm of the possible right now, and those would be very overt, direct signals that would be, not just to our level of the industry, but it would also start to give us the latitude to go and start incentivizing our supply chain to keep up and provide the stuff we need from them,” he said.

As for the investments already being made, Petters said “we’re investing into the [Ohio Replacement Program, or Columbia-class ballistic missile submarine] program. We’re investing into the things we learned as we went through the construction of the Ford (aircraft carrier), we’re making some investments in those areas that are going to drive cost out of the Ford (class). And a billion and a half dollars kind of runs the whole gamut.”

Among the technologies being leveraged is a “smart shipyard” idea that would connect employees all around the yard via wireless internet and tablets, and allow them to do their work based on 3D “digital blueprints” instead of traditional 2D drawings. Since Petters announced last February that the third Ford-class carrier, the future Enterprise (CVN-80), would be the first paperless ship, and Newport News Shipbuilding president Matt Mulherin last May described his dream for a digital shipyard, Petters said the company has been hard at work testing out their ideas.

“We keep running pilots and demonstrators to the workforce, saying, this is how this could work and give us some feedback as to whether that makes sense or not,” Petters said.

“It’s all been very very positive for us, and we’re continuing to be excited about the future.”

This type of digital work environment could generate 15-percent cost savings on Enterprise, Mulherin said last year.