The Navy could cut Ohio Replacement Program (ORP) missile tube acquisition costs by 25 percent if Congress granted a “continuous production” authority that would allow the U.S. and UK ballistic missile submarine replacement programs buy the tubes at a steady pace, according to a recent report obtained by USNI News.

The Navy will further cut costs based on authorities Congress has already granted by looking at common components across ORP, the Virginia-class attack submarine program and the Ford-class aircraft carrier program, according to the Report to Congress on the Ohio Replacement Acquisition Strategy and National Sea-Based Deterrence Fund Accountability, sent to Congress earlier this week by Navy acquisition chief Sean Stackley.

In the report, the Program Executive Office for Submarines was tasked with identifying how authorities already granted by Congress would help save money and time and reduce risk on ORP, and what opportunities there were for further savings if Congress approved further assistance.

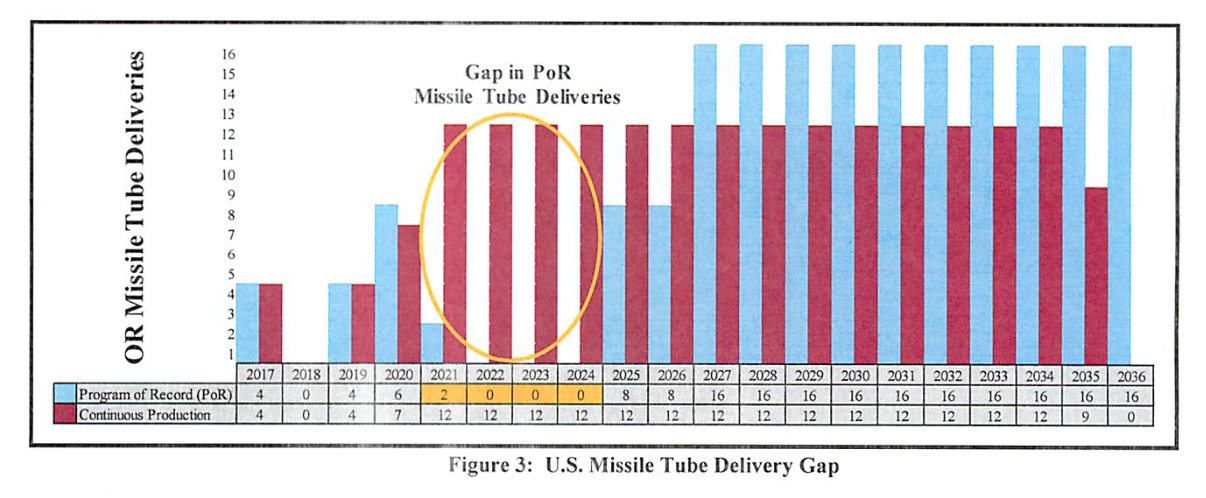

The report recommends a new authority called continuous production, which the Navy would apply just to missile tubes and missile tube modules for now. By taking the total amount of work for the U.S. and UK programs and spreading the workload evenly across between now and 2035, the Navy would create “savings through manufacturing efficiencies, increased learning and the retention of critical production skills. In addition to lowering costs, Continuous Production would reduce schedule risk for both the U.S. and UK SSBN construction programs and minimize year-to-year funding spikes,” the report reads.

The report recommends a new authority called continuous production, which the Navy would apply just to missile tubes and missile tube modules for now. By taking the total amount of work for the U.S. and UK programs and spreading the workload evenly across between now and 2035, the Navy would create “savings through manufacturing efficiencies, increased learning and the retention of critical production skills. In addition to lowering costs, Continuous Production would reduce schedule risk for both the U.S. and UK SSBN construction programs and minimize year-to-year funding spikes,” the report reads.

Rather than the current missile tube production profile – which currently calls for four in 2019, six in 2020, two in 2021, zero in 2022 to 2024, eight in 2025 and 2026, and then 16 each year 2027 through 2036 – PEO Subs mapped out a scenario that calls for 12 a year from 2021 until 2035.

“Missile Tube Continuous Production could achieve an average reduction of 25 percent in Missile Tube procurement costs across the class” compared to the current acquisition schedule, the report notes, and adds that the Navy will look at other build rates to see if any other scenario produces even further savings.

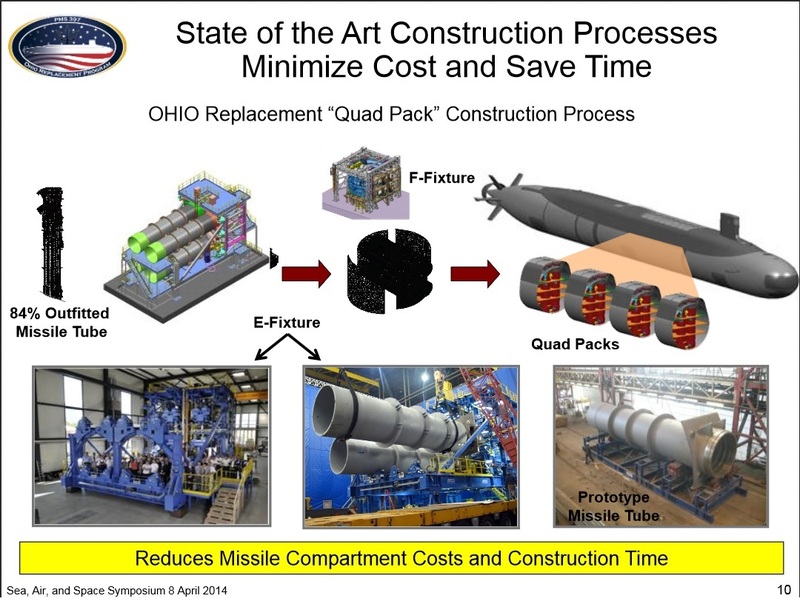

Once the missile tubes are delivered, the shipbuilders will then package four together into quad-packs, and then several quad-packs will be joined together to create a single missile tube module that will be installed on the ship. Applying the same continuous production method to missile tube module manufacturing would produce a 20-percent cost saving, on top of what was already saved on the missile tubes themselves.

Funding would be needed earlier under this plan, which would increase the cost of the ORP in the current five-year Future Years Defense Program, but the report states that continuous production “results in significant overall program reductions.”

The report does not include a projected savings total but notes that the ORP’s Milestone B cost estimate, due to the Pentagon’s acquisition chief in August 2016, will reflect the efficiencies outlined in the report.

If granted by Congress, the Navy would look for other opportunities to apply continuous production within nuclear and non-nuclear components in the ORP, Virginia-class and Ford-class programs, according to the report.

The House Armed Services Committee included continuous production authority in its version of the Fiscal Year 2017 National Defense Authorization Act, released earlier this year.

HASC seapower and projection forces subcommittee ranking member Rep. Joe Courtney (D-Conn.), whose district includes part of the General Dynamics Electric Boat yard, told USNI News on Wednesday that despite pushback on the National Sea-Based Deterrence Fund from some lawmakers in previous years, the submarine piggybank and the extra contracting authorities it includes are undeniably helping the Navy, industry and the country.

“I feel very confident … that the case just gets stronger as time moves on for the fund,” he said, adding that including the continuous production authority was his top priority while working on this year’s defense bill.

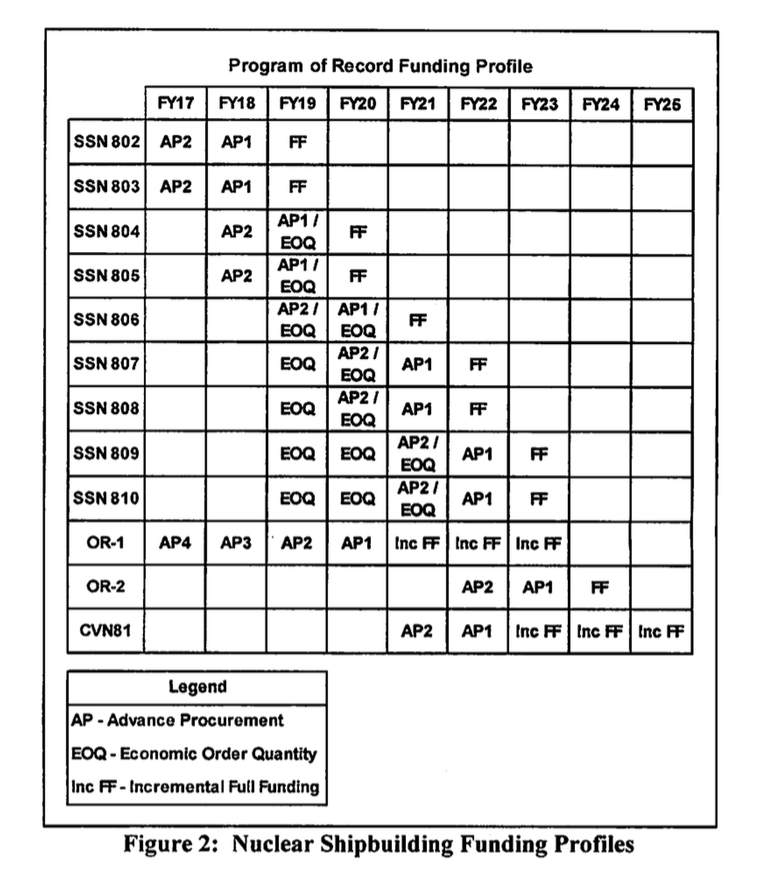

The report also outlines the efficiencies the Navy can create through the authorities already granted by Congress in the FY 2015 and 2016 defense bills. The Navy can now enter into economic order quantity (EOQ) contracts, thanks to last year’s defense bill, which ”provide substantial cost savings to the Navy from procuring materials and equipment in bulk quantities.

“In addition to the cost savings typically associated with EOQ authority, the Navy has identified an opportunity to implement EOQ procurements to achieve (Ohio Replacement) schedule efficiencies and commonality contract actions with (Virginia-class submarine) Block V and CVN (aircraft carriers),” according to the report.

“Coordinated and cross-platform procurements will optimize production facility utilization, stabilize the nuclear shipbuilding industrial base, and eliminate costly production surges and gaps. … EOQ allows vendors to optimize their raw material purchases, human and capital resources, and establish most efficient manufacturing framework which results in reduced cost and schedule.”

Specifically, this authority allows the Navy to pull some work up in FY 2019 through 2021, buying Virginia-class sub parts ahead of the first ORP in 2021, CVN-81 in 2023 and the second ORP in 2024.

Last year’s defense bill also included provisions that allow the Navy to buy some long-lead materials incrementally using both advance procurement and shipbuilding money, and to start some construction activities ahead of the boat being put on contract to help reduce schedule risk and ease the transition from design to construction, according to the report.

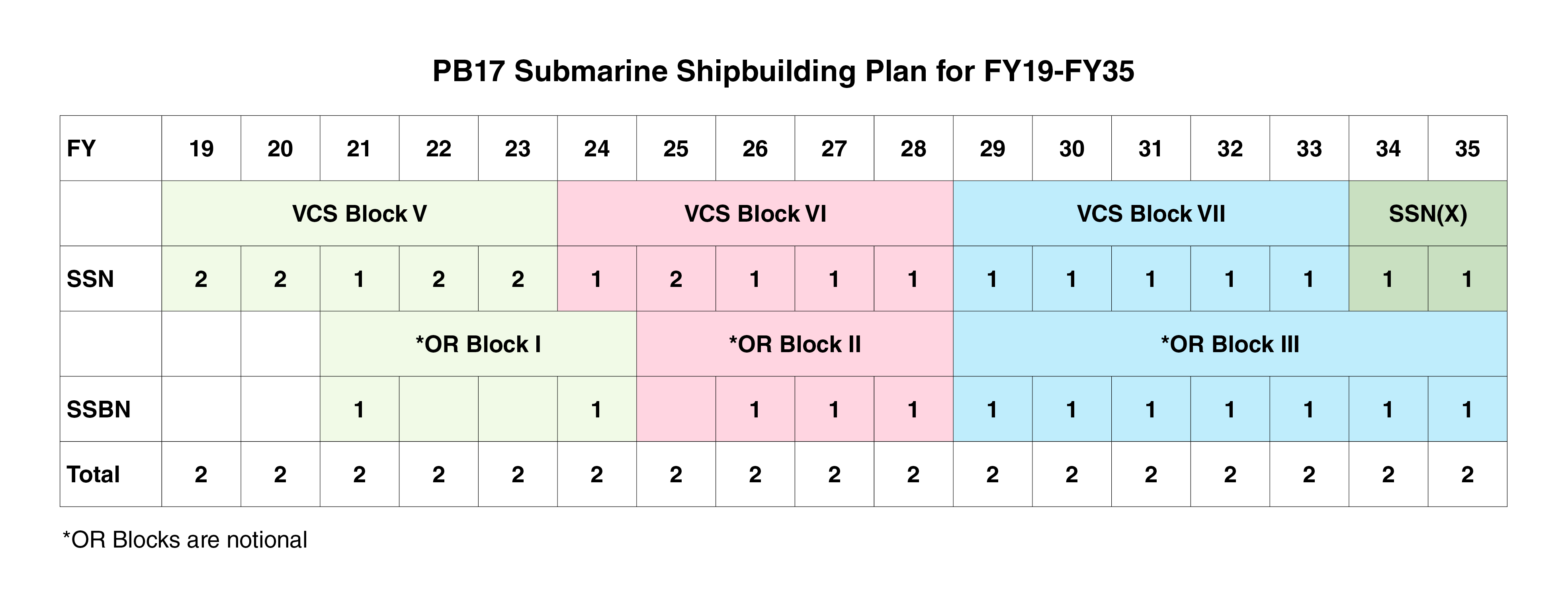

While designing its build plan, the Navy opted to split the Ohio Replacement boats into blocks that line up chronically with the Virginia-class submarine blocks – making it all the easier to put common components under contract and take advantage of the authorities granted by Congress.