PHILADELPHIA, Pa. – Inside the high-ceiling building that was once a World War II aircraft factory, construction is underway on the engineering site where future generations of U.S. Navy sailors will learn to operate the systems aboard the new Constellation-class frigate.

The Philadelphia Navy Yard – while no longer an active U.S. naval shipyard – is still home to the land-based test and land-based engineering sites for the service’s large and small surface combatants. Navy personnel and sailors share an open campus with designers and merchandisers, as the corporate headquarters of URBN – which owns clothing and lifestyle brands like Urban Outfitters and Free People – is next door.

It’s here, just a few yards from the Delaware River, where U.S. sailors for decades to come will learn how to use shipboard systems before deploying at sea on the Navy’s Arleigh Burke-class destroyers, the Zumwalt-class destroyers, soon the Constellation-class frigate (FFG-62), and eventually the program now known as DDG(X).

“Ten years in the Navy, I’ve served on destroyers, which we have here at the test site,” Lt. Christopher Girouard, a representative for the frigate program manager, told USNI News. “It took me until I came here to see the impact to me as a sailor, that Philadelphia had on me.”

For the frigate program – currently under construction at Fincantieri Marinette Marine in Wisconsin – the LBES site will reside in a building known to local Navy personnel as 77 High, on the banks of the Delaware, facing New Jersey. In a prior life, the building was the Naval Aircraft Factory that produced aircraft beginning in 1917 through World War II.

For the frigate program – currently under construction at Fincantieri Marinette Marine in Wisconsin – the LBES site will reside in a building known to local Navy personnel as 77 High, on the banks of the Delaware, facing New Jersey. In a prior life, the building was the Naval Aircraft Factory that produced aircraft beginning in 1917 through World War II.

“LBES is tactical equipment … this means shipboard equipment in a shipboard representative architecture with shipboard representative environment,” Sean Brennan, the director of research, development, testing and evaluation at the Naval Surface Warfare Center, Philadelphia, told USNI News last month during a visit to the site.

“That really drives what we’re going to do and how we’re going to test something. And then how we’re going to lay it out, how we have to configure it,” Brennan added.

While the LBES acts as a testing bed to prove different versions of software configurations before going out to the fleet, the LBTS focuses on hardware, as a laboratory of different configurations to settle on a final propulsion system.

The propulsion system for the Constellation is a new configuration for the U.S. Navy, with a combined diesel-electric and gas turbine system. The CODLAG propulsion system takes a General Electric LM-2500+G4 and combines it with two MTU diesel engines to power the ship via an electric drive system.

NSWC Philadelphia is currently in the initial demolition phase and is repairing the roof over the section of Building 77 High that will house the frigate LBES.

“This entire area between the DDG-51 LBES and the end of the building will serve as the FFG-62 LBES in a few short years, which will include tactical ship equipment that will be operational for the entire lifecycle of the ship class,” Brandon Weiss, the LBES program manager for DDG-51, told USNI News.

Navy officials often cite the LBES and LBTS sites in Philadelphia to show that the service is doing its due diligence to test out systems early to ensure they work properly. But generations of sailors will use the LBES throughout the service life of the Constellation class to learn the program’s shipboard equipment before going to sea.

In accordance with the Fiscal Year 2021 National Defense Authorization Act, the Navy must finish the LBES site for the frigate before the lead ship in the class delivers in 2026. The site must include shipboard equipment for systems ranging from the main reduction gear and the main propulsion system, to the power control modules.

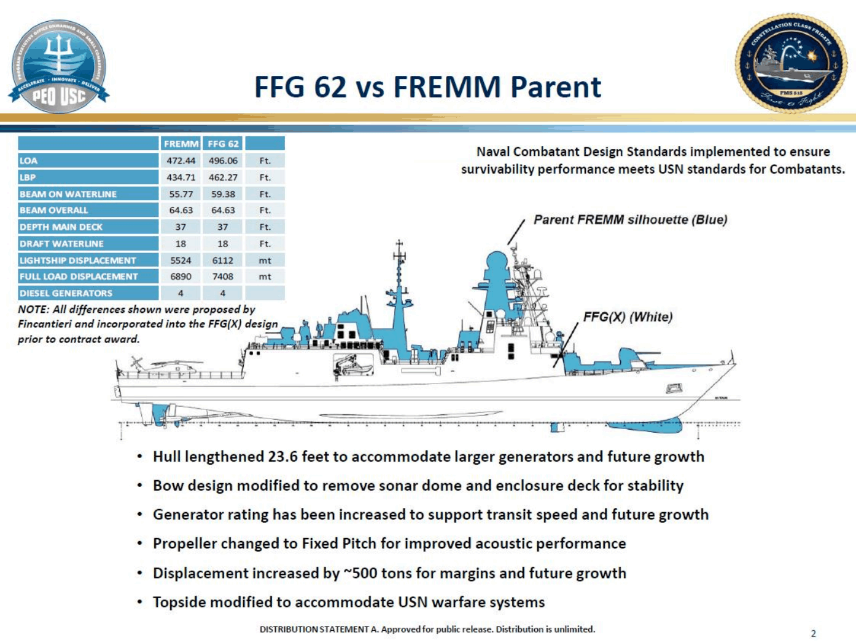

The frigate is primarily designed for anti-submarine warfare, to move quietly on the surface with no direct mechanical connection to props, but generate power for a ship-wide electrical grid. The parent design for the Constellation-class ships, the Italian FREMM multi-mission frigate, uses a similar configuration.

During the visit to Building 77 High, Girouard, a former surface warfare officer who has served on the Avenger-class mine countermeasure ships and the Arleigh Burke-class destroyer, described the LBES sites in Philadelphia as an integral part of how sailors proficiently operate the fleet’s surface assets across the globe.

“I have deployed a couple of times out in [U.S.] 5th Fleet and stood engineering watches. I was always confident that my equipment worked. When I got an order from the bridge, saying, ‘online start all offline GTMs,’ when we’re doing torpedo evasion maneuvers, that it was going to work every time. I guess I didn’t know where the confidence came from and the work that got us to be confident in it,” Girourd, standing in front of the future testing site for DDG(X), told USNI News.

“And so I came here and saw where all this stuff comes from, that the reason why I knew this stuff was going to work was because these people in this organization have been working on it since, well for DDGs, since at least 1989,” he continued. “To me, that’s kind of the personal connection I found by working here, that the work that we do is so tied to the sailor and sometimes can be so transparent, but strong. It’s a foundation where you don’t realize the work that someone put into it. So I guess it’s kind of how I view Philadelphia now in a different light than I probably did ever, as a sailor, even if I never came here.”