For three years in a row, the Navy has requested $40 billion annually to build, operate and sustain its ships, but the service has put insufficient thought into how early decisions could reduce those sustainment costs in the future, according to a Government Accountability Office new report.

Each year the Navy spends billions of dollars on shipbuilding, but the acquisition phase only accounts for about 30 percent of a ship program’s total life-cycle cost, according to the GAO’s Navy Shipbuilding: Increasing Focus on Sustainment Early in the Acquisition Process Could Save Billions.

Approximately 80 percent of a ship program’s long-term sustainment costs are determined by decisions made early in the acquisition process, according to the report’s analysis of shipbuilding programs during the past ten years.

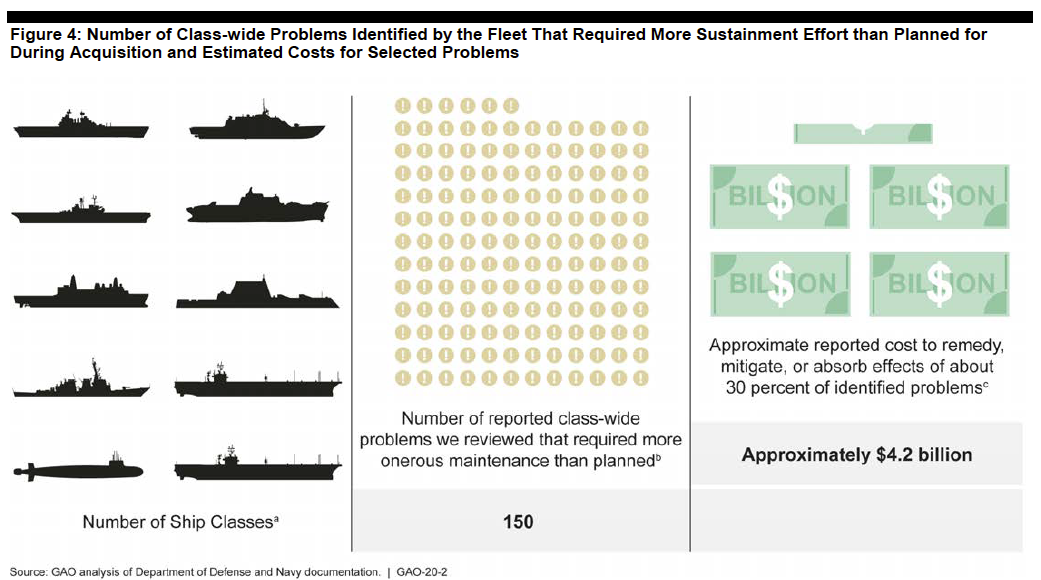

However, the report’s authors said they found 150 problems affecting multiple ship classes that resulted in increased costs and effort to correct than what was initially expected. The GAO did not publicly release the list of problems, but vaguely described them as being related to poor early planning in the shipbuilding program.

Now, as these ships operate in the fleet, the Navy is often required to make repairs or create workarounds for problems the GAO report authors say could have been avoided with better planning for sustainment planning.

“In particular, we estimated that the Navy’s fleet has spent or is planning to spend at least $4.2 billion to mitigate and correct approximately 30 percent of these problems beyond what was planned for during the acquisition process,” the report states.

The key to avoiding many of the preventable maintenance problems is taking steps to test out sustainment assumptions early in a program’s development. The Navy is starting to perform this work, but the results are uneven, according to the GAO report.

The decisions, once made, are tough and costly to change if sustainment improvements are needed. The report cites a problem with the Ford-class toilets. The toilet and sewage system on the ship is similar to what is installed on commercial aircraft but on a much larger scale. The system is prone to clogging which will require a periodic acid flush. This unplanned maintenance, the report states, will cost about $400,000 each time.

“Chemical cleaning of the [sewage] piping takes place on Navy ships to include Nimitz-class carrier [USS George H.W. Bush] (CVN-77) and all Ford-class carriers. These cleanings are a maintenance requirement,” Capt. Danny Hernandez told USNI News on Wednesday. “On average the chemical cleaning is completed every three to five years for carriers, and for Navy ships such as DDGs, and LPDs. The chemical cleaning is not more difficult on Ford-class than Nimitz-class, nor is the cost expected to be different.”

“The Navy is kind of in this little conundrum right now with regard to trying to do everything it needs to do to get the amount of ships that it thinks it needs, but also maintain and sustain the ships that it already has,” Shelby Oakley, the GAO’s director of contracting and national security acquisitions, said during the GAO podcast The Watchdog Report.

In a letter responding to the GAO report’s findings, Navy acquisition chief James Geurts explained steps the Navy has taken to consider sustainment costs.

“The Navy has improved sustainment reporting, accountability, processes and emphasis in program decision in the past decade, and they continue to be a constant focus,” Geurts wrote.

The Navy updated its acquisition process to focus on sustainment matters early in program development, Hernandez said. The Navy is strengthening its Independent Logistic Assessment, Life Cycle Sustainment Plan and Sustainment Program Baseline Processes.

One example of the Navy working on nailing down long-term sustainment costs during a program’s planning phase is how the Navy is running the Columbia-class ballistic-missile submarine program, Oakley said on the podcast. Columbia has a dedicated product support manager in charge of considering the long-term sustainment costs of the program. The 12 Columbia-class submarines are designed to operate with lower maintenance requirements so they can sufficiently replace 14 Ohio-class subs while keeping the same number of subs on patrol.

“The whole concept of the Columbia class replacing the Ohio class is really predicated on being able to quickly perform your maintenance and get your subs back out into operations. And so, we are seeing, you know, some different approaches on the Columbia-class submarine from that perspective,” Oakley said in the podcast.

On the flip side, Oakley and the team of GAO analysts found the Navy’s approach to developing the new class of guided-missile frigate risks creating a program prone to unexpected delays and sustainment costs. A dedicated product support manager hasn’t been appointed, and the Navy plans to award a contract this summer.

“The program has now made critical sustainment decisions, such as developing the sustainment strategy, the maintenance and training schedule, and the sustainment key performance parameters, without a PSM,” the report states.

Without a dedicated PSM, the report’s authors worry the Navy could be on the path to developing another program plagued by problems, many of which could have been anticipated or avoided.

“The requirements set that we saw would result in a ship with, that would be absolutely not available the amount of time that the Navy needs it,” Diana Moldafsky, one of the report’s contributors said during the podcast, referring to requirements not yet publicly released.

When looking at the 150 problems across ship programs, the GAO researchers found the problems could be easily divided into three categories: maintaining commercial equipment on ships, ship designs that did not effectively consider maintainability, and untested sustainment assumptions. During the past 10 years, these problems resulted in maintenance delays and caused operational ships to defer maintenance longer than what was expected or recommended.

“What struck us in our audit work in talking with the sailors and the engineers and the spare parts logisticians and various other members of the fleet maintenance operations community is just how frustrated they are with the condition of some of the new ships that they’re asked to operate. And that frustration was very palpable to us and something that struck us as key through this review,” Laurier Fish, one of the report contributors, said during the podcast.